Design+Build Engineering

SME Mechanical provides a complete mechanical package to successfully meet the needs of today’s complex HVAC system designs.

Our project managers have extensive experience and training managing projects with cost-effective strategies. Their advanced technical know-how ensures budgets are met and long-term system obligations are achieved.

We plan ongoing maintenance to provide maximum efficiency – and comfort – throughout the life of your custom system.

In addition to the mechanical system, SME Mechanical knows the value of our customer relationships. You will find our company embodies the spirit of service, professionalism and mechanical aptitude. We invite you to find out why.

Our design+build engineering services for HVAC mechanical and piping include:

- Integrated Project Delivery (IPD) and Building Information Modeling (BIM)

- Detailed estimates

- Building energy analysis

- Code review

- AutoCAD drawings produced in-house

- HVAC systems and analysis

- Process piping systems

- Sanitary waste systems

Below are a few examples of design+build engineering projects from our growing list of clients. Contact us to learn how we can assist with your project needs »

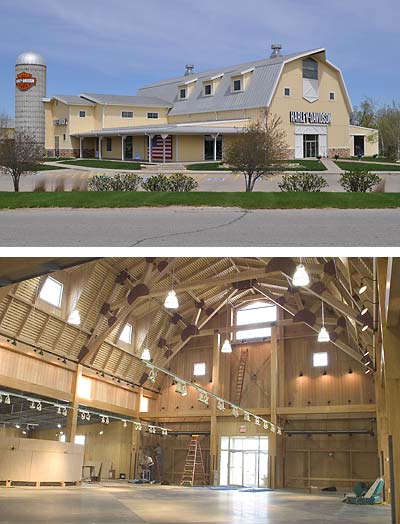

Big Barn Harley-Davidson

Des Moines, Iowa

This project involved the design+build of a new 34,000 square foot specialty retail space. Design was to encompass the look of a rustic Iowa barn with the latest features of modern ventilation. A variable-air-volume (VAV) system was sized and zoned for sales area, parts and services counter and the company’s office space.

We were challenged to produce ductwork to match the aged galvanized ductwork already in place. After experimenting with various metal finishes, our shop was able to match new duct to the existing look.

Big Barn presented a second challenge – detecting and managing carbon monoxide in the shop while maintaining proper air pressure in the showroom and ensuring that no odors crossed from the shop to the showroom. We accomplished this goal by using a simple, yet effective 80/20 MAU with integrated DX coil, carbon monoxide sensors, differential pressure sensors and simple logic controls.

Midwest Healthcare Textile Services

Des Moines, Iowa

This design+build of a new 54,000 square foot industrial laundry facility project included an extra twist which required us to meet the American Institute of Architects (AIA) Guidelines for Hospital Construction, which includes certain ventilation rates and airflow movement between soiled and clean areas, plus summer cooling for occupants on a non-profit organization’s budget.

To satisfy these requirements, ventilation rates and pressure differential were maintained with the use of constant volume and variable volume MAUs. We also used spot cooling by converting off-the-shelf rooftop units to 100% outdoor air units. Typical construction included HVAC, plumbing, process piping and exhaust.